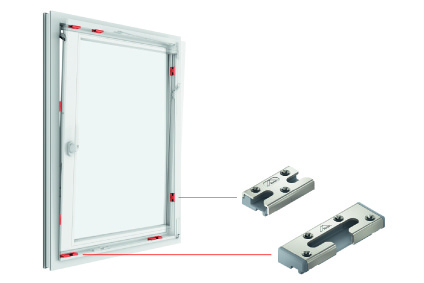

Customers making higher level security windows can now take advantage of a newly revised range of steel frame components.

The new versions standardize the appearance of the range, with all strikers now comprising a steel outer part on top of a plastic or zinc base.

Steel framed strikers can be specified for both PVC and timber windows, usually for security specifications designed to meet the requirements of EN Resistance Class 3.

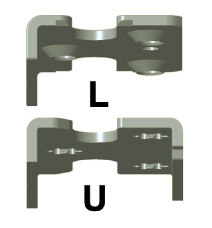

PVC versions

On PVC, the new designs differ from the previous versions in that the steel part is now an overarching “U” shape, rather than the “L” shape found on the older models.

This provides a high level of dimensional stability and improves the optics, with more steel being visible.

Timber versions

The steel strikers for timber, which previously were made only from folded metal, have been brought into line with the other designs, moving from a “G” to “U” shape.

They now feature a plastic base, including end pieces which create a neater appearance and prevent dirt and debris entering the striker.

Automation compatible

All steel strikers will now come in two standardized lengths, being either 50 or 86.5 mm long. This helps make them more compatible with automated systems, as does the fact they have a secure and firm connection between the top and bottom part with no ‘play’.

The bases of the strikers contain feed grooves, designed for use with Lemuth window manufacturing machines.

Symmetrical parts

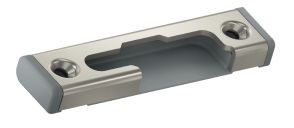

Another benefit for fabricators is that those tilt strikers which previously were left- or right-handed have been replaced with symmetrical designs. This reduces the number of different parts that need to be held or ordered. Having universal strikers for all windows regardless of handing also means they are more easily processed in automated production.

The new symmetrical tilt strikers have four screw fixing holes instead of three, providing even greater stability and security.

Aesthetics

A closer look at the new striker range reveals more improvements. The surface of the steel now has a premium quality appearance. Each striker has a Roto logo embossed into it, although options are also available for the embossing of customer logos onto specially ordered batches of strikers.

The visual appearance of the new strikers is cleaner than before. There are no clip holes on the front edges of the components and there is no longer any riveting of the steel parts onto the zinc bases, so there are no longer any visible riveting dies. The move away from riveting has also eliminated the chances of the steel parts being damaged and weakened during the riveting process.

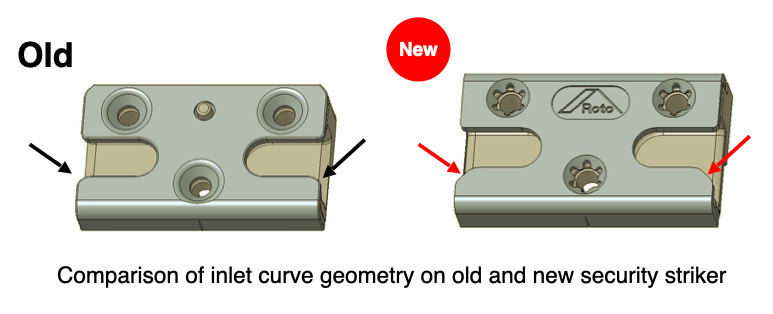

Modified geometry

On the striker slots, the geometry of the inlet curves has been modified in order to make it easier for the cams to begin their travel into the striker slots. This reduces the operating forces required to close the window – something that is especially useful on RC3 specifications which have a high number of locking points.

Screw fitting

Two of the countersunk screw holes on the 50mm timber strikers and all three holes on the PVC versions are now “star shaped” as standard. This is designed to enable faster and more accurate fitting of the strikers by making it easier to keep drilling tools stable.

E-Tec ready

The steel strikers are supplied ‘ready to use’ with Roto MVS and MTS contact elements. The base area of the strikers do not have to be reworked. It is therefore even easier to use them as part of windows on homes or buildings with electronic monitoring and control systems.

Download full details

To download the full product information documents, fill in the form below.

By completing and submitting the form below, you agree to our privacy policy.