The 18th edition of our group’s annual International Press Day took place in Graz, Austria in November. Roto directors reported positive financial results and looked ahead to 2024 with a focus on new product development, growth via acquisitions and a continued focus on the implementation of new technologies.

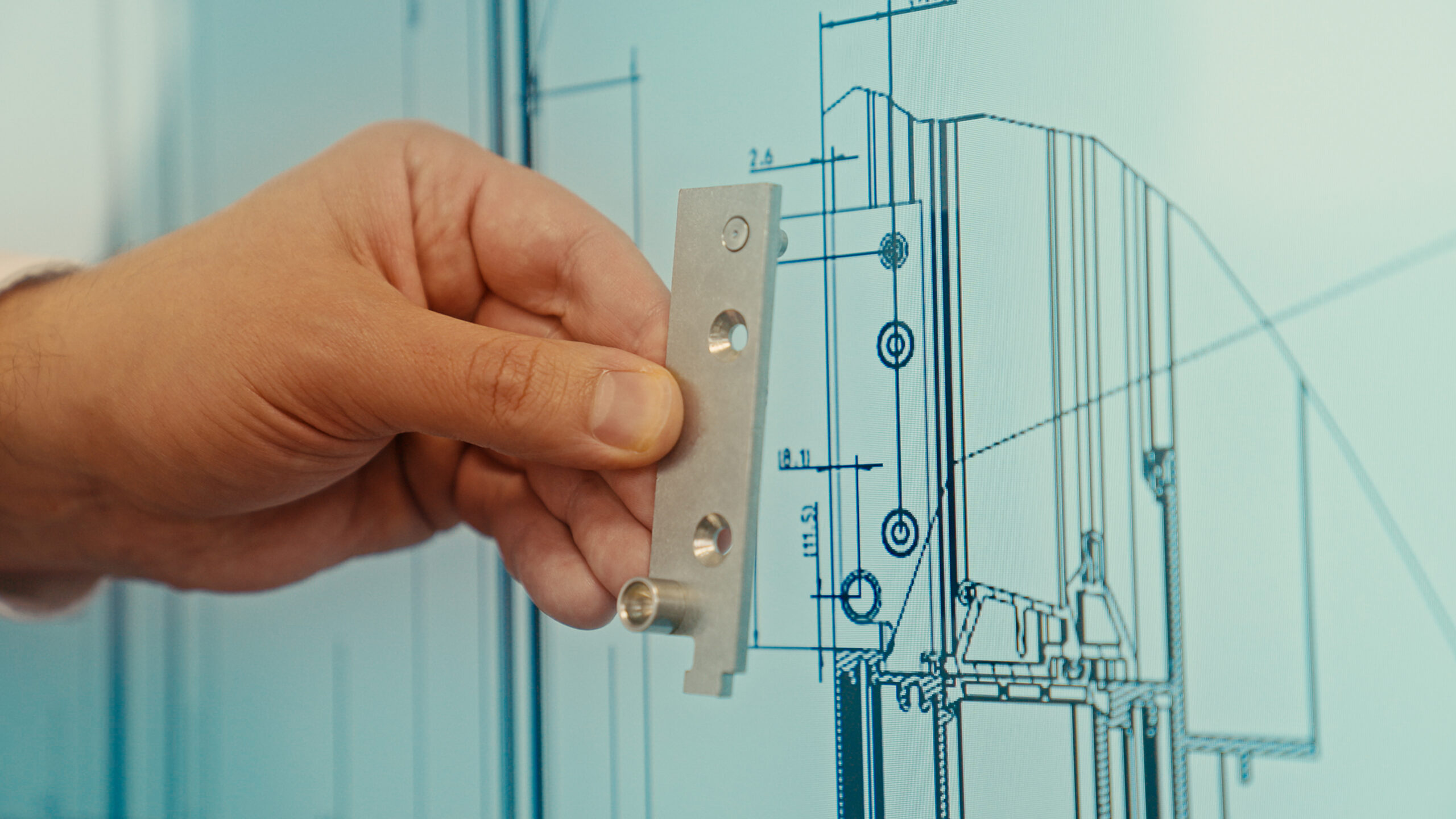

On the afternoon of their arrival, delegates were given a comprehensive tour of the facilities at the Roto Kalsdorf production site, which primarily produces door locks, door hinges and window hardware and is one of the most versatile of Roto’s eighteen worldwide factories. Visitors also saw the recently expanded door test centre, which has 27 rigs and conducts every type of recognised test on door sets to assist both Roto engineers and partner companies in product development.

“Build the future, now”

The main day’s press conference, attended by an additional contingent of journalists via a livestream, began with an address from group chair Dr Eckhard Keill, who chose the theme “Build the future, now”. As that title suggests, he used his address to call on the fenestration industry to lobby governments to do much as possible to encourage new construction as well as the renovation of existing buildings.

Increased turnover figures

Dr Keill recalled how in May 2023, Roto group overall turnover was 7 per cent up on the figure from the previous year due to strong demand from many international markets. By contrast, the second half of the year had been more difficult. He said that in the last two weeks prior to his address, things may have slightly improved.

With all this in mind, he was predicting that Roto would end 2023 with a turnover increase of 2 per cent compared to 2022. He said that making a prognosis for 2024 was even more difficult than it had been for this year, because the number of variables to take into consideration is higher again. Nevertheless, he is confident that Roto can have another successful year.

Reliable partner

Marcus Sander, CEO of Roto Window & Door Technology, started his presentation by reporting that more building element manufacturers had begun a relationship with Roto over the last year or expanded their existing collaboration. “This is due to the reliability of the support we offer”, he said. One of his main themes was the idea that Roto is much more than a manufacturer, being “a consistently reliable partner” that gives added value in every area of business.

Hardware and weatherseals

He went on to discuss how the Roto sealing brands, Deventer in Europe and Ultrafab in the USA, provide customers with a wide choice of weatherseals that are designed to work precisely with Roto hardware systems. He said that not only were requirements for energy efficiency of buildings increasing, but there was also a bigger need for storm resistance now that extreme weather events are becoming more common. “Tightly sealed windows and doors are becoming increasingly important for environmental protection and the safety and comfort of people”, he said, explaining that this is why more and more customers are consulting with Roto for advice on both hardware and sealing systems combined.

Modular systems

With regard to hardware systems, Mr Sander explained how Roto was committed to a “modular principle”, in which engineers strive as much as possible to use common components that can be used on as many opening types and frame materials as possible, thereby reducing complexity and bringing greater efficiency and economic benefits for window and door manufacturers.

Special solutions

“We already either have a perfect solution, or will work with the customer to develop it”, he said of the Roto Object Business experts, who are part of the wider Roto Aluvision aluminium systems team. This group of advisors works with aluminium window manufacturers to find solutions to challenges of making non-standard windows for specific buildings. Over the last decade, Roto Object Business has worked on windows for a number of prestigious construction projects around the world, supplying special specifications and dedicated components and assisting with manufacture and installation.

Testing services

As another example of the added value of a partnership with Roto, Mr Sander talked about how customers around the world are able to get their window or door designs tested at one of Roto’s laboratories. “With our extensive test facilities, Roto can save our customers time and money with this service”, he said.

Expanding European customer base

Mr Sander was keen to emphasise how Roto has moved on from being a brand known mainly for tilt and turn hardware, and is now known for successful products in the sliding and door sectors. He said these product groups were a significant factor in gaining new business in Europe, with manufacturers of residential doors appreciating Roto as a “single source supplier of locks, hinges and thresholds”. He cited Patio Inowa sliding hardware as being “unique” because it allows construction companies to specify sliding systems in areas where they could not previously be used, such as on high rise buildings, due to the extreme weather resistance provided by its locking and sealing technology.

Future investments

Over the year ahead, Roto will continue to develop its production facilities with the aim of reaching climate neutrality. Reliability of power supply is another focus: the company is committed to finding more ways to generate power from renewable sources. As well as the environmental protection benefits, this approach also helps to ensure a consistent power supply, which is another way in which Roto is able to be a reliable and dependable supplier for window and door manufacturers.

“We have an optimistic view of the future”, said Marcus Sander. “Roto is continuously investing to further improve the climate footprint of our industry and to remain a consistently ideal partner”.

Roto Frank Professional Service division

Also at the Press Day, Dr Christian Faden, CEO of Roto Frank Professional Service, made a presentation on how this division had grown its turnover by more than 50% in the last year and, after a series of acquisitions, now owned 33 company sites in Germany, Austria and Switzerland offering repair and renovation services for windows. This is currently the sole marketplace for Roto Professional Service.

He also showed the results of a scientific study involving tests on real windows, which proved that replacing hardware and gaskets to improve sealing characteristics can reduce the heating costs of a building by up to 15%.

Designo Heat Roof Window

Meanwhile, Christoph Hugenberg, CEO of Roto Roof Systems Technology, showed a new product that he described as “a game changer in the renovation market”. The Designo Heat roof window has an invisible infrared panel in the glass that radiates heat into the living space. The rationale behind this product is that it makes it much easier to convert attic spaces into living areas, because complex work such as routing heating pipes is avoided. It can be installed and commissioned just like any other electrically powered roof window model in the Roto range.

New Window & Door products due in 2024

During his presentation, Marcus Sander said that Roto Window & Door Technology will be present at the Fensterbau Frontale trade fair in Nuremberg in March 2024, and will be showcasing a number of new products.

In all, the stage is set for a very interesting 2024 from Roto. There has never been a better time to look at making us your window and door hardware, technology and weatherseal supplier. Use the form below to make an appointment with your local Roto representative and find out exactly what we can offer your company.

Book a consultation

Catch up with your local Roto representative. Fill in your details here and they will be in touch to arrange it with you.

By completing and submitting the form below, you agree to our privacy policy.