- Brand new version to run alongside existing Patio Inowa system.

- Designed for much larger glazed areas – up to 400 kg sash load.

- Ball bearing technology for ultra-smooth, low friction operation.

If you have been following the story so far, you will know that Roto Patio Inowa has made a big impression worldwide because of its ultra-tight weathersealing. This advantage is due to its patented closing mechanism and brings benefits such as high wind resistance, noise reduction and improved energy efficiency.

Where is Patio Inowa going next? The answer is, bigger.

While the system has been growing in popularity and seen use on major architectural projects from London to Mexico City, our team of development engineers have been working behind the scenes on a project to create a new version for larger, heavier sliding elements.

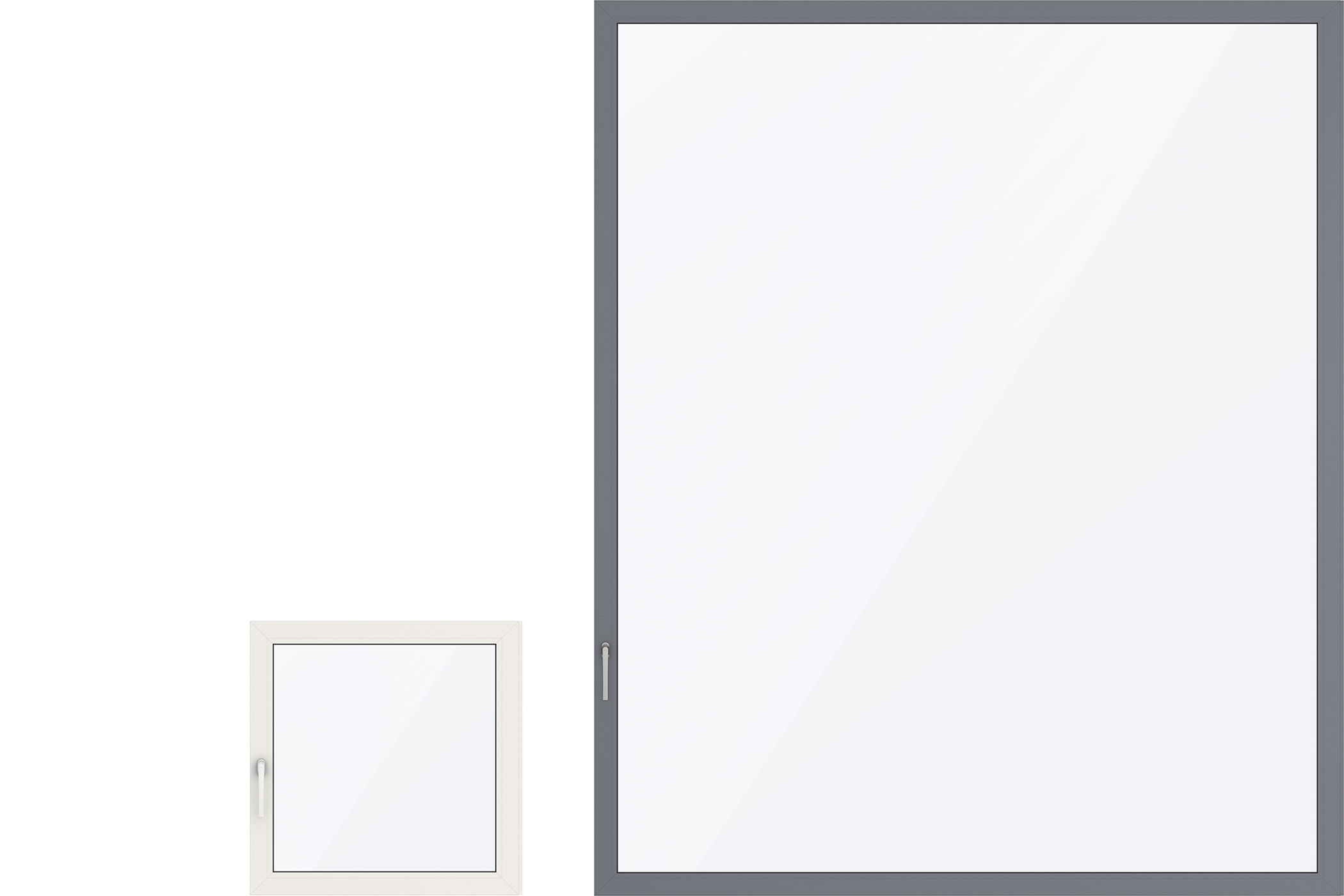

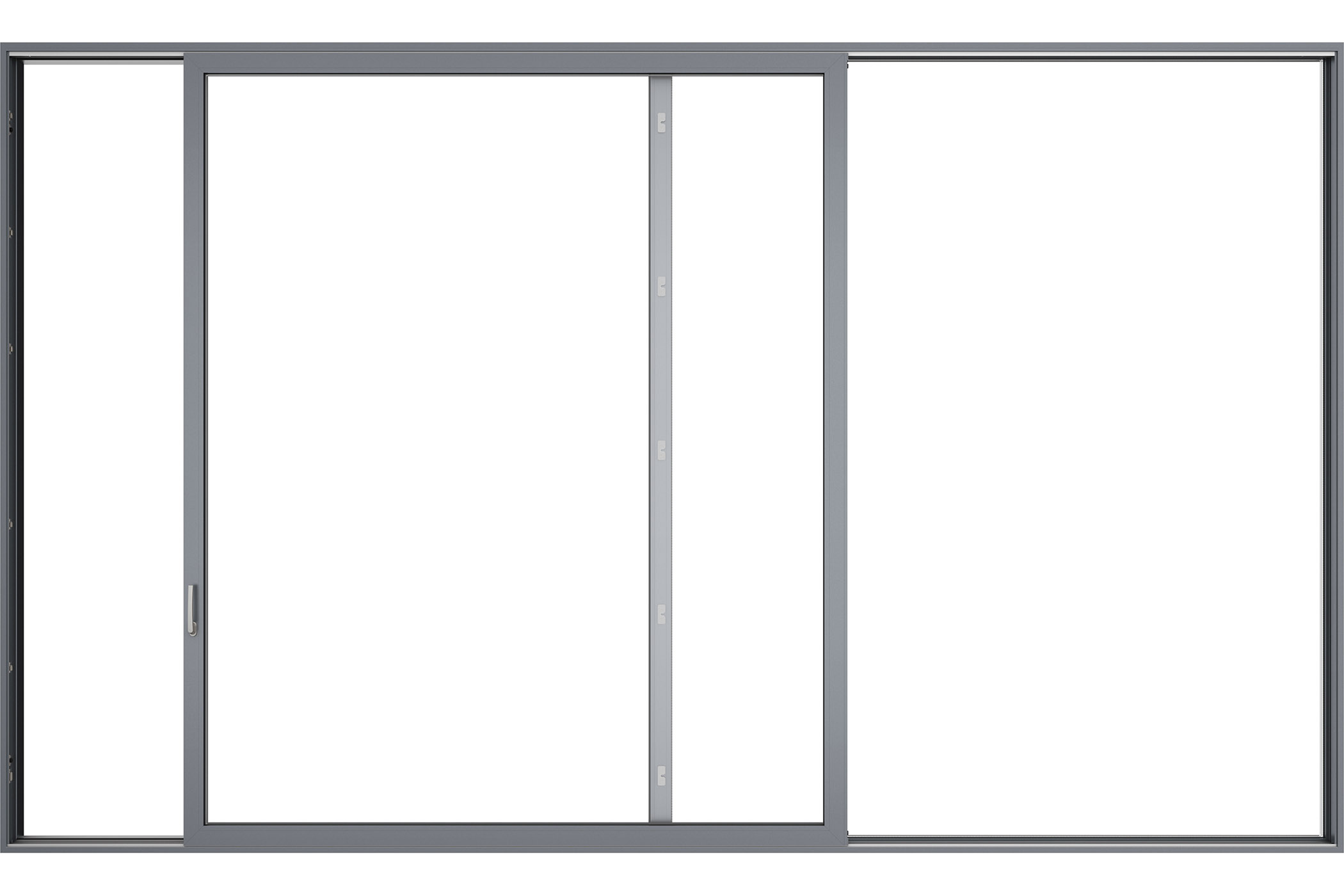

The result is Patio Inowa 400. This means the system will be available in two different versions:

- Patio Inowa 200 – The original version. Maximum sash loading 200 kg (Maximum rebate sizes: width 2000mm; height 2500mm).

- Patio Inowa 400 – The brand new version. Maximum loading 400 kg (Maximum rebate sizes: width 3000mm; height 3600mm).

With these new maximum dimensions, Patio Inowa 400 is now a viable alternative to a Lift&Slide system.

Here are a few highlights of Patio Inowa 400:

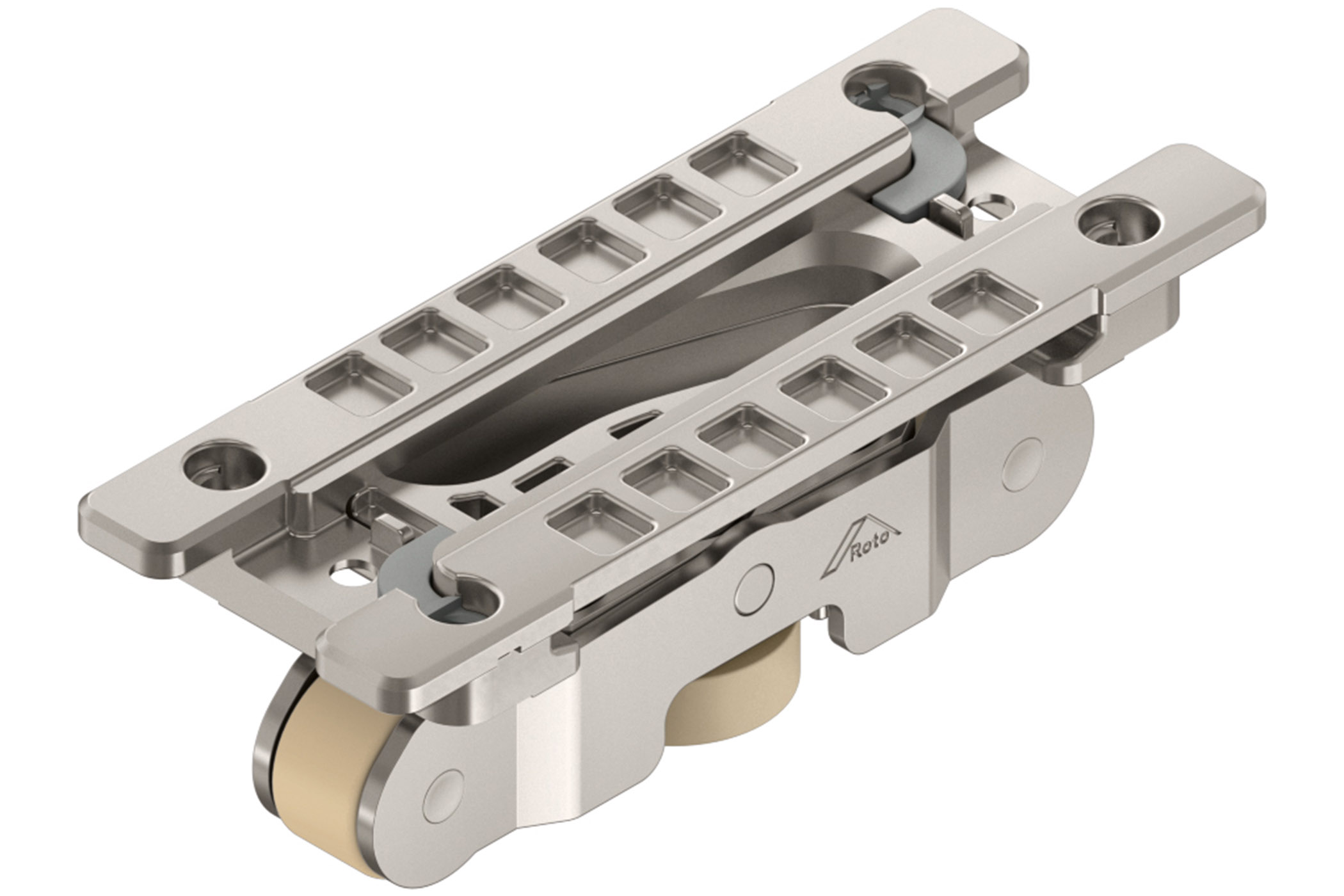

Ball bearings

Although the basic principle of the Patio Inowa mechanism remains the same, the new components for the 400 series make use of ball bearings. This ensures that the smoothness and low operating forces for which Inowa is known are retained, even at the higher loadings.

At lower loads, the system is so incredibly light to operate, it could be sold as a premium alternative to Patio Inowa 200, for those customers who appreciate a higher level of refinement.

Roller units

The new roller units are mounted on ball bearings, which is the key to their smooth operation. These rollers are longer than the Inowa 200 versions, requiring six fitting screws instead of four.

Integrated brushes help to keep dust and debris away from the wheels.

The rollers are height adjustable with a 4mm hex key. As an example of the attention to detail the engineers have put into this project, the hexagonal hole has a chamfered edge to make it easier to insert the hex hey.

Stabilisation unit

Depending on the width of the sash, one or two of these devices will be specified. They help guide the sash during the sliding action and also play a role in helping to maintain gasket compression when the unit is closed and locked.

K-cams

This brand new cam type is found on extensions designed for PVC, timber and timber-alu profiles. The K comes from “Kugelgelagert”, the German word for “ball bearing mounted”.

As this name suggests, these cams incorporate ball bearing technology. They help to make the locking action smooth and keep handle torque forces low, even on larger sashes with higher numbers of locking points.

D13 control cams

This is the equivalent of the K-cam for use on aluminium profiles. Whereas the D8 control cam for Patio Inowa 200 is made of one part, this cam is made of two parts and integrates a ball bearing. Again, it results in a very low level of friction, making locking the hardware easy.

SoftStop

This function is available up to the maximum loading of 400 kg. It is therefore always possible to have a sash that is brought to a damped stop at the end of the sliding action.

The SoftStop function can be fitted on both the espagnolette or mullion side and used to damp both the opening and closing actions.

Magnetic lock monitoring

You have the option of fitting a striker incorporating a concealed MVS device for monitoring the locking status and detecting tampering. This can be connected to a smart home system and allow the homeowner to know whether the sliding unit is open or locked. It can also be connected to a burglar alarm to provide monitoring in accordance with VdS Class B.

Fast, simple assembly

Patio Inowa 400 is designed to be as quick and easy as possible to fabricate. Each of the main items requires only a few screws to fit it. A common jig is available, enabling workers to prepare the screw positions for the rollers, control units and stabilisation units.

Find out more about Patio Inowa 400. Download the literature and then get in touch with your Roto representative to arrange a demonstration.

Download full details

Get the brochure here. Please fill in and submit your details to get the document in your inbox..

By completing and submitting the form below, you agree to our privacy policy.