As a door manufacturer, you want the maximum amount of function and flexibility from a product range; at the same time you need to keep the number of different parts you have to order and process to a minimum.

Our design engineers focused on these considerations when they embarked on a project to revise our range of one-piece striker plates for residential doors.

The result is a 58% reduction in the number of different components along with a number of new advantages for fabricators.

The project was conducted using a 10 point plan. Here is a summary of each with the benefits it brings to you:

1. New modular system

The previous AS series has been replaced by four size classifications. This has reduced manufacturing costs, which means we can minimise price increases and invest more in further product development. Fewer parts also means less complex ordering and stockholding for fabricators.

2. Reduction in different lengths of parts

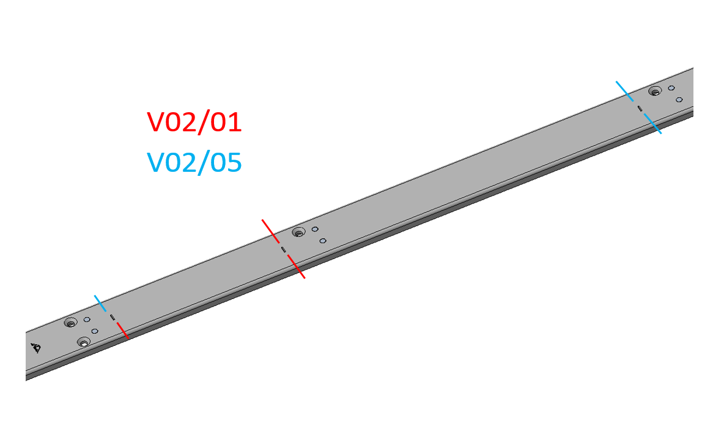

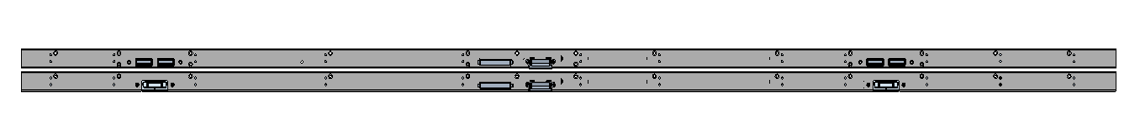

Instead of making three different faceplate lengths, we now provide one length of faceplate. In order to achieve the two shorter lengths, the faceplate is cropped in specific positions and the two halves butted together. The cropping marks have been strategically placed in order to keep all locking points and screw positions in the correct positions.

You can achieve patterns V02/01 and V02/05 by cutting down a V02/03 faceplate in accordance with markings provided on the strips. This provides another cost saving as fewer variants need to be ordered and held in stock.

3. Standardised screw position between latch and bolt

This fixing point is now on all faceplates in order to provide a better security performance across the entire range. A screw fixing between the latch and deadbolt increases the stability of the striker plate and enhances the break-in resistance of the door set.

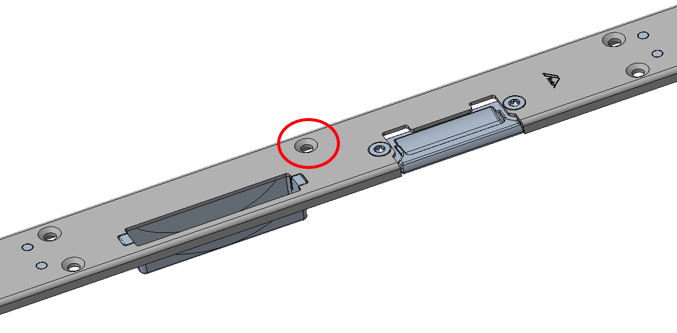

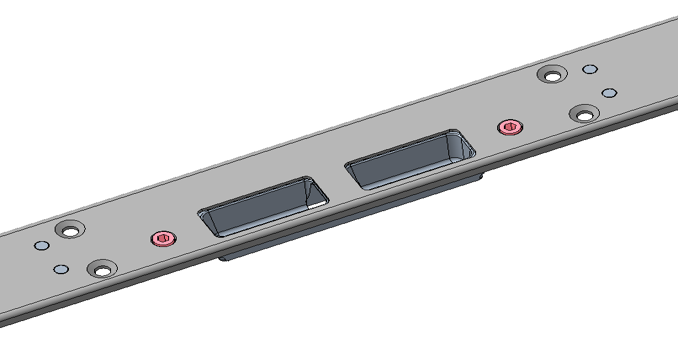

4. Drilling position for magnet

On all 2C striker strips there is now a small pre-stamped hole marking the drilling position for a universal magnet. If a magnet is required for use in conjunction with electromechanical door locks, the hole can be drilled to expand it to the required size.

This achieves further variant reduction because any striker strip can be used with electromechanical locks and special versions are not required. It is also time-saving in production because the drilling position is clear.

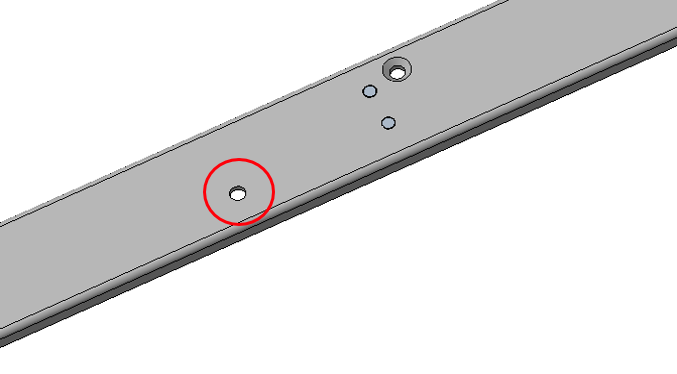

5. Harmonised screw positions

Another fabricator-friendly amendment. Striker plates for 2C and 2A locking point types are now completely interchangeable due to having identical screw fixing positions. The same screw pattern can now be used for both types, reducing complexity in production.

(picture on top: old version – picture at bottom: new version)

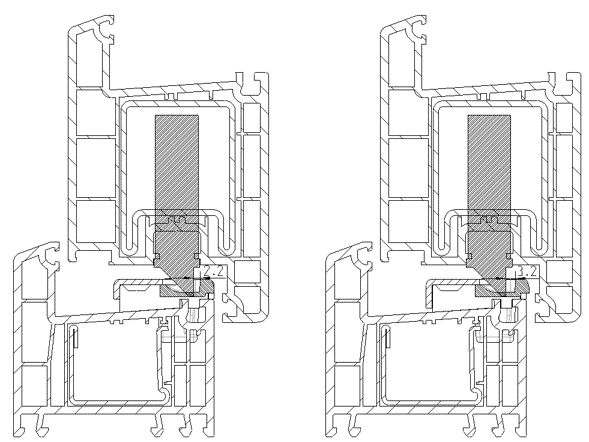

6. Standardised 1mm gasket compression on PVC and timber

This will help increase service life of hardware by reducing stress on components. Profile tolerances are absorbed and a lower operating force is required, which helps make your door locks easier to use.

7. Second screw located 7mm from front (U29 and U35 only)

This is another improvement to help increase the ability of the installation to resist break-in attempts. For you, a chance to improve Resistance Class capability and a selling point to your customers.

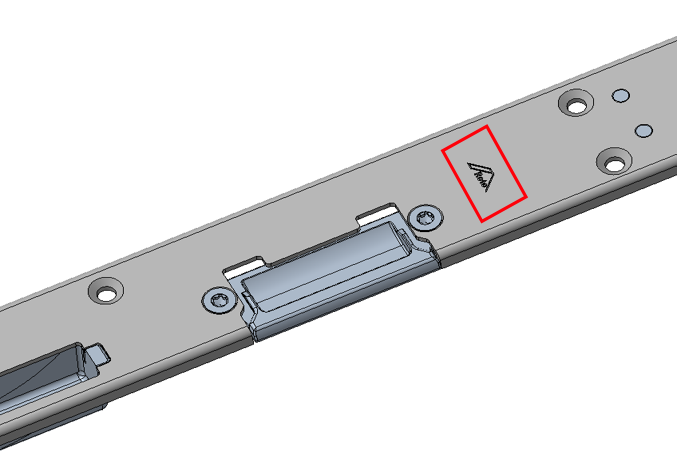

8. Roto logo on all faceplates

There is now consistent branding across the range, with the logo present and in the same position on every faceplate. You can use the Roto brand to provide customers with the assurance of quality in every area, from mechanical reliability to corrosion resistance.

9. Reduction in number of articles

Where there were previously 523 articles in the range, there are now 220. This new range is made up of 170 universal parts and 50 profile-related items.

As stated previously, this brings down the total number of items by 58%. A significant reduction in complexity with many savings in logistics and processing.

10. Transparent price structure

There are now eight price categories, depending on the faceplate size and locking point combination. This should help you have a clear pricing structure, so you can cost your door sets accurately.

- If you are currently using one-piece striker strips, the technical details we have made available will show you all the differences between the outgoing and new product ranges.

- If you have not used these products and are interested in these or any other part of the Roto Door Safe range, please contact your dealer or Roto representative for more information.

Download technical information

Fill in your details and download the full technical documentation here.

By completing and submitting the form below, you agree to our privacy policy.