Weather performance testing is arguably the most exacting indicator of the overall quality and construction of a window. We met with Martin Barck, the experienced head of the Roto International Test Centre in Leinfelden to find out more.

Photography is not allowed in the Roto International Test Centre. From the overhead gallery we get a view of a range of windows and doors undergoing various tests. Automated rigs can be seen opening and closing windows repeatedly. One window shows the signs of a recently-completed manual break-in test.

The reason for the secrecy is that the centre often tests customers’ windows as part of the Roto ITC’s position as a neutral, accredited laboratory. Research work on Roto Group prototypes and products at various stages of development also takes place here.

The Roto ITC covers a total floor area of 1,400 square metres and is clearly very well-equipped. Every type of testing for windows and doors can be conducted: burglar resistance, endurance, handle torque, material and corrosion testing.

30 years experience

Today though, we have dropped by to talk specifically about weather performance testing. Our host is Martin Barck, manager of the Roto International Test Centre. Martin has 30 years experience in the field of window and door testing, and we hope to learn a bit more about what happens when windows are tested for air and water resistance and subjected to wind loading simulations.

Accredited laboratory

“We have the status of an accredited laboratory”, explains Martin. “This means we have to be completely neutral in the way we conduct the testing in accordance with established standards. We can also issue test reports to individual customers. These reports can help them with their own product development and internal quality procedures”.

Martin explains how EN standards work with regard to weather testing. “In each part of weather testing there are two standards. The first defines the test method. The second is concerned with how to classify the window based on the test results and observations”.

We now take a look at each of the weather performance tests in more detail:

Air Permeability

This test is designed to measure how much air will pass through a window or door installation under the pressure of wind.

“Windows and doors do not have to be completely air tight, but the amount of air that can get in has to be kept below a certain level”, says Martin.

“Here, we build the window into a testing unit”, he explains. “Then we run a testing cycle that involves both positive and negative pressures. For a higher performance test, for example to Class 4, we would be using a maximum pressure of 600 Pa”.

The calculation of the air tightness is based on the length of the gasket. Martin tries to simplify it for us: “For example, a square window with a gasket of 1 metre on each side would have a total gasket length of 4 metres. Our final figure is based on the amount of air that passes through 1 metre of gasket. This enables a proportional comparison of different sized windows”.

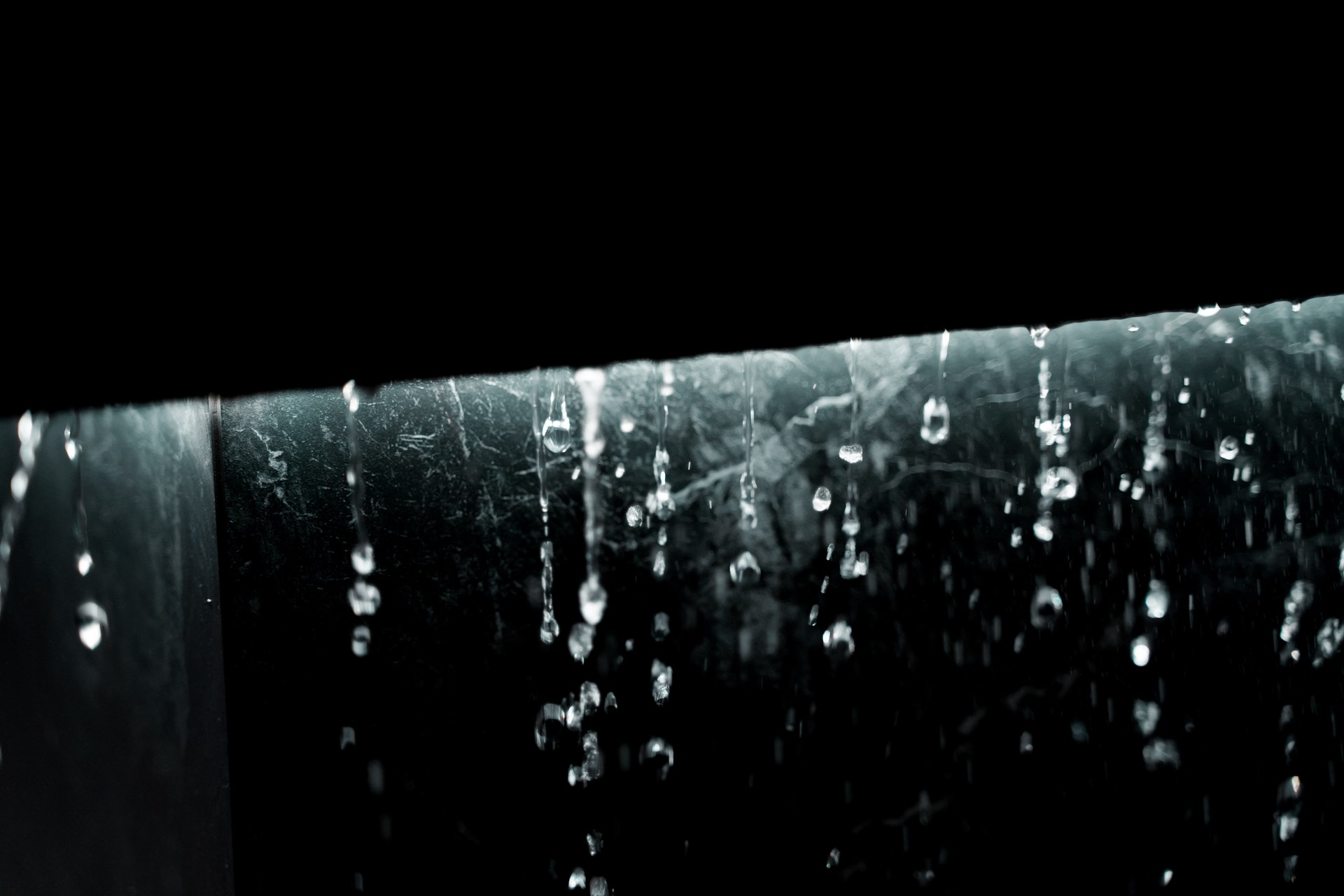

Water tightness

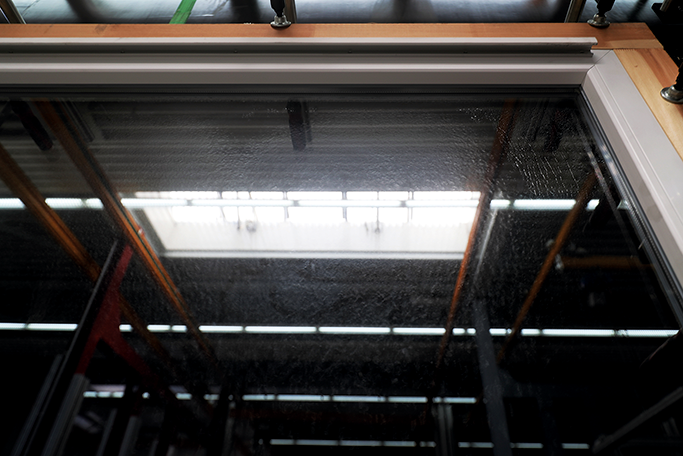

In this test, water is sprayed over the window and the air pressure is increased to replicate the conditions of a rainstorm.

“The number of spray jets depends on the width and height of the window”, Martin says. The standard is written to ensure that the entire window is covered with a constant stream of water all the way across and from top to bottom.

The test takes place over a maximum of 55 minutes, during which time the air pressure is increased every 5 minutes up to a predefined level, depending on the test category.

“As soon as water is observed entering on the inside of the window, we stop the test”, says Martin. “The window is classified at the last level where it was resisting the water”.

Wind resistance

The deflection test is often the most dramatic part of the entire weather testing process for observers, particularly when large installations are subjected to wind loads and the deflection is very visible.

The wind resistance element actually comprises four parts. The deflection test is the first of these.

Next, a mechanical test in which both positive and negative pressures are applied in a repeating cycle 50 times over.

A wind pressure test is then conducted to check that the window remains securely in place. Finally, there is an air permeability test.

“The tests that take place after deflection are to check that the window still operates and performs to standard after it has been exposed to the high loadings”, Martin explains.

Final thoughts

“These tests are very tough for the window”, Martin states. “For example the pressure of 600 Pa, which is a common classification, is equivalent to the kind of air pressure you would get from a wind of 120 km/h. These are the sort of weather conditions where trucks can be blown over and trees uprooted”.

“Modern windows are able to stand up to these tests very strongly, so long as they are well made. Roto hardware and Deventer seals will help any window to maintain a consistent air and water resistance”.

“At Roto we have the experience and knowledge to help fabricators to solve their specific requirement — individual advice for their window, their project. The knowledge of our engineers can help the customer specify their windows in the best way to pass these air, water and wind tests. Talk to your Roto representative first for advice, and we can then provide you with a test conducted neutrally and in strict accordance with standards”.

Book a consultation

Catch up with your local Roto representative. Fill in your details here and they will be in touch to arrange it with you.

By completing and submitting the form below, you agree to our privacy policy.